Fluidized Beds

How it Works

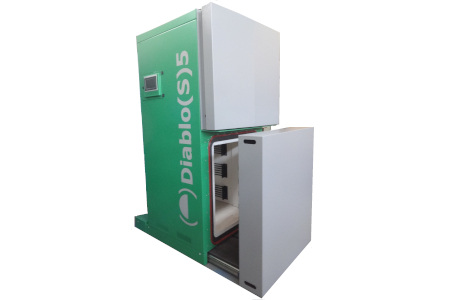

The main part of the Fluidbed Cleaning System is an insulated reactor containing sand particles.

Sand is heated by a flame on the bed surface. The reactor is directly heated using a

‘flame-shield ’ at the bed surface in order to achieve temperatures around 450°C.

Parts do not come directly into contact with flames.

Though not turbulent enough to be abrasive, the sand gently rubs the surface

leaving the metal completely paint-free and undamaged. The fluidised sand ensures that

the parts are subjected to an even temperature profile to avoid distortion.

Sand is heated by a flame on the bed surface.

Parts to be cleaned do not come directly into contact with flames.

The paint is thermally degraded within the sand bed and the toxic gases are then oxidised at the bed

surface using the ‘flameshield’. Inorganic particles are abraded by the sand particles and, blown out

of the sand bed and captured in a filter system. Safe, clean, fast and environmentally friendly: words

that are not normally associated with this type of cleaning!

The Fluidbed Cleaning system from Arena provides a fast, low cost,

environmentally friendly method of removing practically all organic contaminants such as paint,

plastic and rubber from steel parts.

Advantages

- Fast, reliable and perfect cleaning,

- High capacity cleaning,

- Safe fluid bed technology due to advanced loading system,

- Perfectly controlled homogeneous temperature

- Low maintenance, long machine life

- No thermal deformation of parts

- Environmentally friendly technology no hazardous waste, no chemicals, recycle heat

- Low running costs.

- No risk of distortion or damage to steel parts due to temperature differences.

- Good cleaning results

- Cycle time 30-60 minutes usually.

- Highly reliable technology

- Versatile: powder, two pack, water-based paints, plastics, rubber, grease all can be removed

Applications

- Paint stripping of hangers, grids, skids, jigs

- Plastic removal from extruder parts, screws, filters spinnerets, nozzles

- Removal of rubber, glue, lacqures, wax coatings

- Degreasing of metal parts

- Hot runner manifold cleaning